Frequent explosions plagued the U.S. grain industry until the Occupational Safety and Health Administration introduced new grain-handling standards in 1988. The number of explosions soon dropped.

Still, grain handling and processing facilities in the U.S. have experienced a 10-year average of 8.4 incidents annually, said Kingsly Ambrose, professor of agricultural and biological engineering. During the last decade these incidents have led to dozens of injuries and fatalities, millions of dollars in damage, and operational downtime.

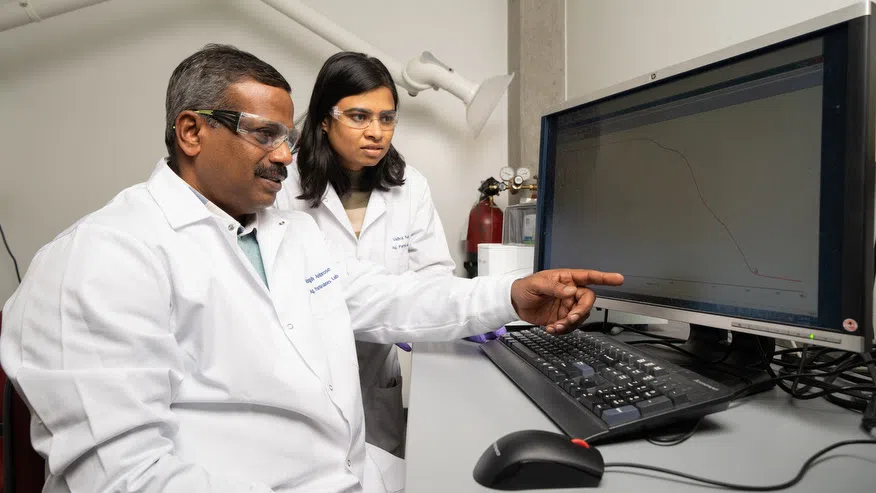

Ambrose specializes in the agricultural applications of particle science. His current work delves into grain dust explosion prevention, improved fertilizers and grain damage modeling. Funding for these projects comes from the U.S. Department of Agriculture, CNH Industrial and Bayer.

“Particle science is helping to develop new controlled- and slow-release fertilizers that reduce the use of chemical coatings,” Ambrose said. “Through better characterization and by structural modifications, we are developing innovative solutions that optimize nutrient delivery in fertilizers, prevent dust explosions, minimize grain damage during harvesting and handling, and improve seed germination.”

In recent years, Ambrose and his associates have patented several processes, including one that measures the amount of light passing through a dust cloud to quantify airborne dust in a grain facility. No previous method enabled grain operators to quickly, easily and continuously monitor dust accumulation in their facilities.

Ambrose and his colleagues disclosed their discoveries to the Purdue Office of Technology and Commercialization, which applied for patents to protect the innovations.

He also has patented an algorithm that uses artificial intelligence to automatically calibrate for the type and amount of dust being measured.

“Depending on the grains, the amount of dust will vary. Corn generates more dust than wheat, for example,” he said. “Properties will also differ, so you want separate calibration for each type of dust,” he said.

The economic stakes of damaged grains are significant. From 5% to 10% of all grains become damaged during combine harvesting or handling and storage.

“Damages could be both internal and external. We lose quality. We lose storability. The value goes down,” he said.

Ambrose blends model development with laboratory testing to identify where most grain damage occurs. His particle science approach reveals what forces act on the grains as they run through a threshing cylinder or a combine harvester. Companies can then apply his findings to improve their systems.

He hopes that a recent grant from USDA Agriculture and Food Research Initiative will lead to further improvement in developing innovative granular urea fertilizers. This work is in collaboration with Carl Wassgren, professor of mechanical engineering, and Kurt Ristroph, assistant professor of agricultural and biological engineering, both at Purdue; and Chad Penn, soil scientist at the USDA Agricultural Research Service.

Ambrose began conducting particle research as a graduate student at Purdue, completing his PhD in agricultural and biological engineering in 2010. He lauded the influence of the interdisciplinary faculty and facilities of Purdue’s Center for Particulate Products and Processes (CP3) on his academic career path. Now he manages the center’s characterization lab, which spans faculty members from the colleges of agriculture, engineering and pharmacy.

“Leveraging the power of particle technology will drive agriculture toward a more sustainable and safer future, helping meet global food demands while minimizing the environmental footprint,” he said. Lowering the cost of production will also be a benefit.

Purdue University

Comments